The word “enamel” may seem very unfamiliar to a lot of people. Some people may remember enamel as part of the teeth, while others may think of it as something only artists and craftsmen would know. But not to worry, we are here to explain to you everything there is to know about enamel and why is it is a great feature in storage tanks.

Enamel is more commonly known as a protective or decorative coating on metal, ceramic and glassware. It is produced by smelting a mixture of inorganic materials at high temperatures. In case you’re wondering what smelting is, it is derived from the German word “smelzan”, which means “to melt”.

The use and presence of enamel date back to around the 13th century BC when six gold rings decorated with vitreous enamel colored layers were discovered in a Mycenæan tomb in Cyprus. Since then, enamel was slowly adapted by many older civilizations, from ancient Egyptians to the Greeks, the Roman Empire and even parts of the Middle East, in which it was used to decorate jewelry and religious artifacts.

Various techniques in using enamel then started developing, including what was believed as the first enamelling of iron in Germany in the 18th Century. This led to the production of enamelled cast iron cooking vessels and sheet iron. From this, the Industrial Revolution paved the way to drive enamel application forward into industrial vitreous enameling, which is present in many home and industrial applications today.

There are two types of enamel, namely painted enamel and vitreous or porcelain enamel.

Painted enamel, at its simplest form, is a type of solvent-based paint that is typically sprayed onto objects to achieve a hard and glass-like shell. It is mostly used for touch-ups and is a convenient way to apply protective coating on things such as bathtubs.

On the other hand, porcelain enamel is a thin layer of glass fused on a metal object at high temperatures. Apart from beautifying the object, enamel helps to strengthen the surface of the object, while helping to minimize scratches and rust.

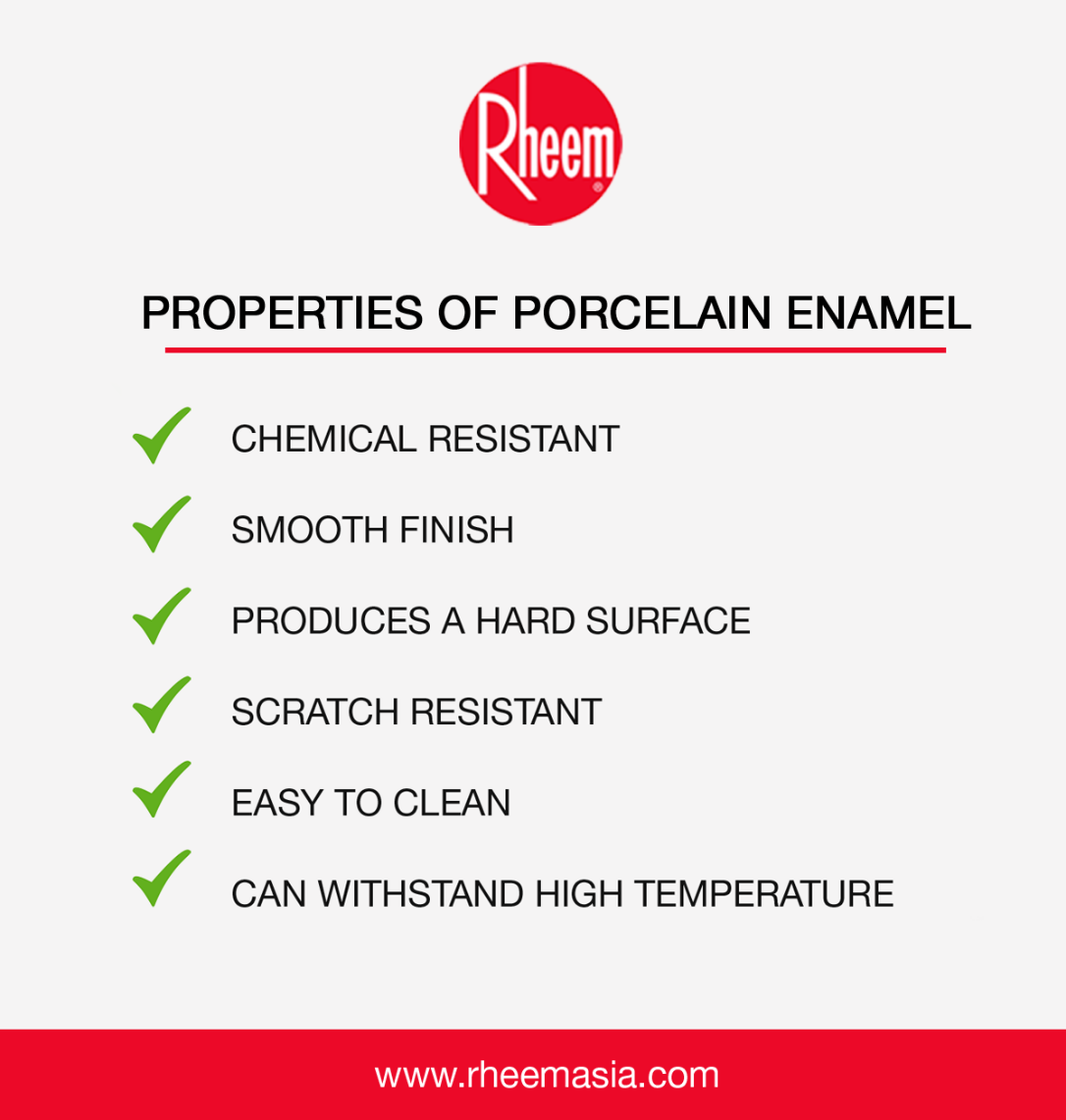

Vitreous or porcelain enamel is known for its special properties such as:

This makes it ideal for many modern applications, both at the workplace and at home. That explains why our bathtubs, sinks, ovens, stoves and some storage water heaters at home all have a glassy finish.

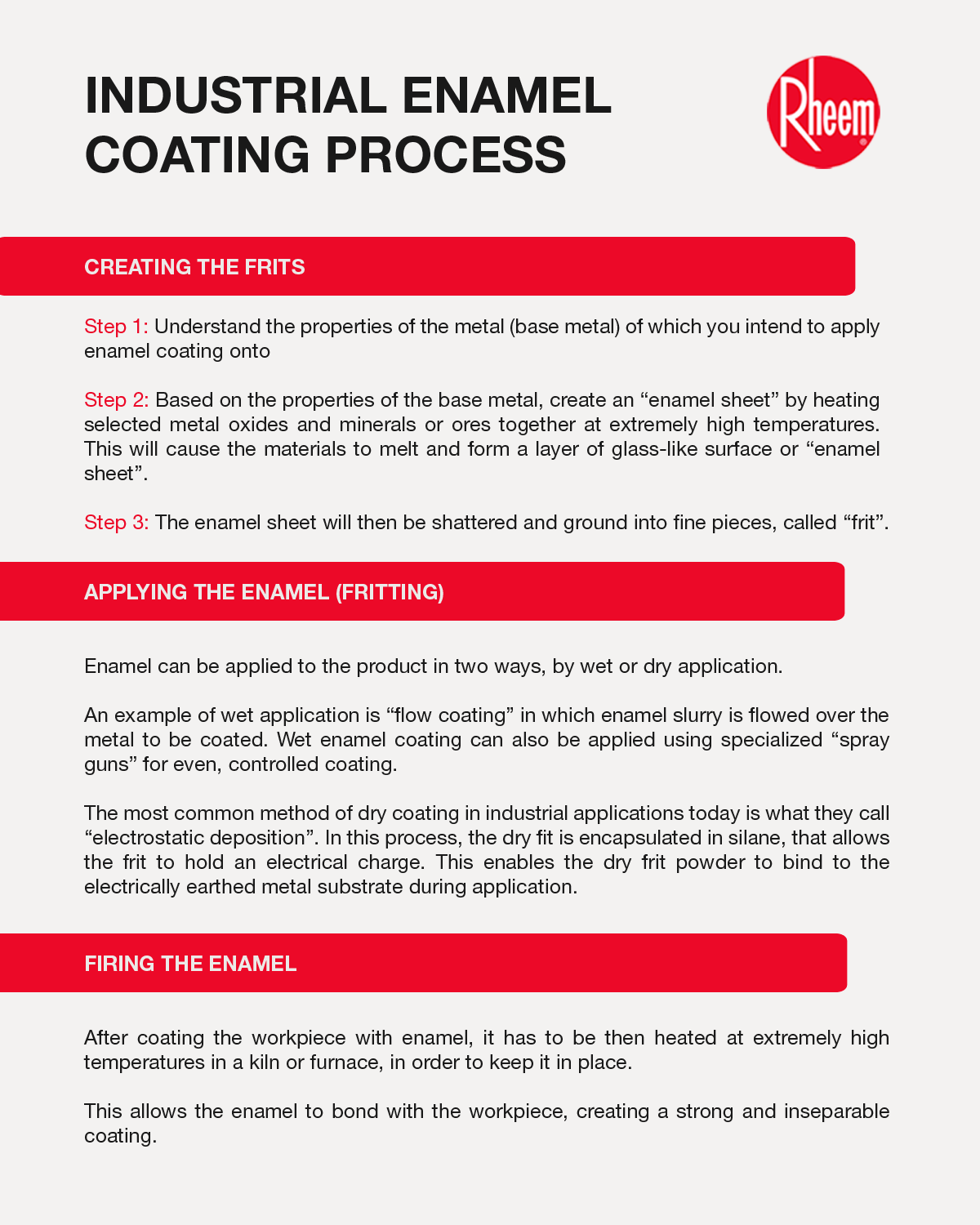

When it comes to storage water heaters, enamel is sometimes used as a protective barrier in the inner tanks. How then is porcelain enamel created? First the enamel is created by combining selected minerals and metal oxides at a high temperature. Once this is cooled, it will form a glass-like surface which will be then ground into fine pieces known as frits. The frits will then be applied to the metal surface or object that you want to coat and will be heated at a very high temperature ranging from 1100° to 1600° F (593.3° to 871.1°C) in order to melt. This process is also known as fritting, which will help the frits create a strong and inseparable coating with the metal surface.

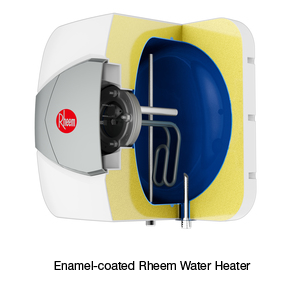

We have seen how durable and high-quality enamel coating can be as it can withstand high temperatures and at the same time offer excellent protection. This is why Rheem’s storage water heater inner tanks are coated with enamel. Here are more reasons why you should choose storage water heaters that come with enamel coat in their inner tanks:

As the leading manufacturer and distributor of water heating solutions worldwide, Rheem’s storage tanks are equipped with enamel coating to provide the quality and durable water heating products to homes and businesses in Asia and all over the world.

To know more about Rheem storage tanks, visit our website at /products/storage-tanks/.

Subscribe

At Rheem, we strive to innovate

best-in-class products to lead the industry

in

environmental improvements.

Sustainability